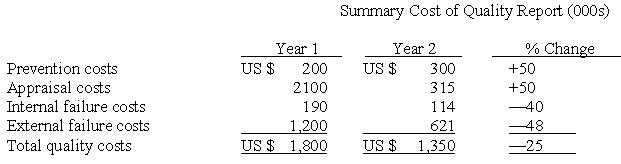

In Year 2, a manufacturing company instituted a total quality management TQM) program producing the following report:

On the basis of this report, which one of the fallowing statements is most likely true?

- An increase in conformance costs resulted in a higher quality product and therefore resulted in a decrease in nonconformance costs.

- An increase in inspection costs was solely responsible for the decrease in quality costs.

- Quality costs, such as scrap and rework, decreased by 48°/O.

- Quality costs, such as returns and repairs under warranty, decreased by 40°l°.

Answer(s): A

Explanation:

TQM emphasizes the supplier's relationship with the customer and recognizes that everyone in a process is at some time a customer or supplier of someone else, either within or outside the organization. The costs of quality include costs of conformance and costs of nonconformance. Casts of conformance include prevention costs and appraisal inspection) costs. Nonconformance costs are composed of internal failure costs and external failure costs, such as lost opportunity. Conformance costs prevention and appraisal) increased substantially, whereas the nonconformance casts internal and external failure) decreased.

Hence, the increase in conformance casts resulted in a higher-quality product.